Tracked Windshifter EcoHog EH1500-TWS | Year: 2025 | Hours: 1

Tracked Windshifter EcoHog EH1500-TWS | Year: 2025 | Hours: 1

EH 1500-TWS Specification:

Accelerator belt details

BLOWER FANS

SEPARATOR DRUM

DISPERSION CHAMBER

WINDSHIFTER HOUSING CONSTRUCTION

CONVEYOR 1 – Light fraction (in-line)

CONVEYOR 2 – Heavy fraction (perpendicular)

HEAD DRUM MAGNET – Heavy conveyor

TRACK FRAMES

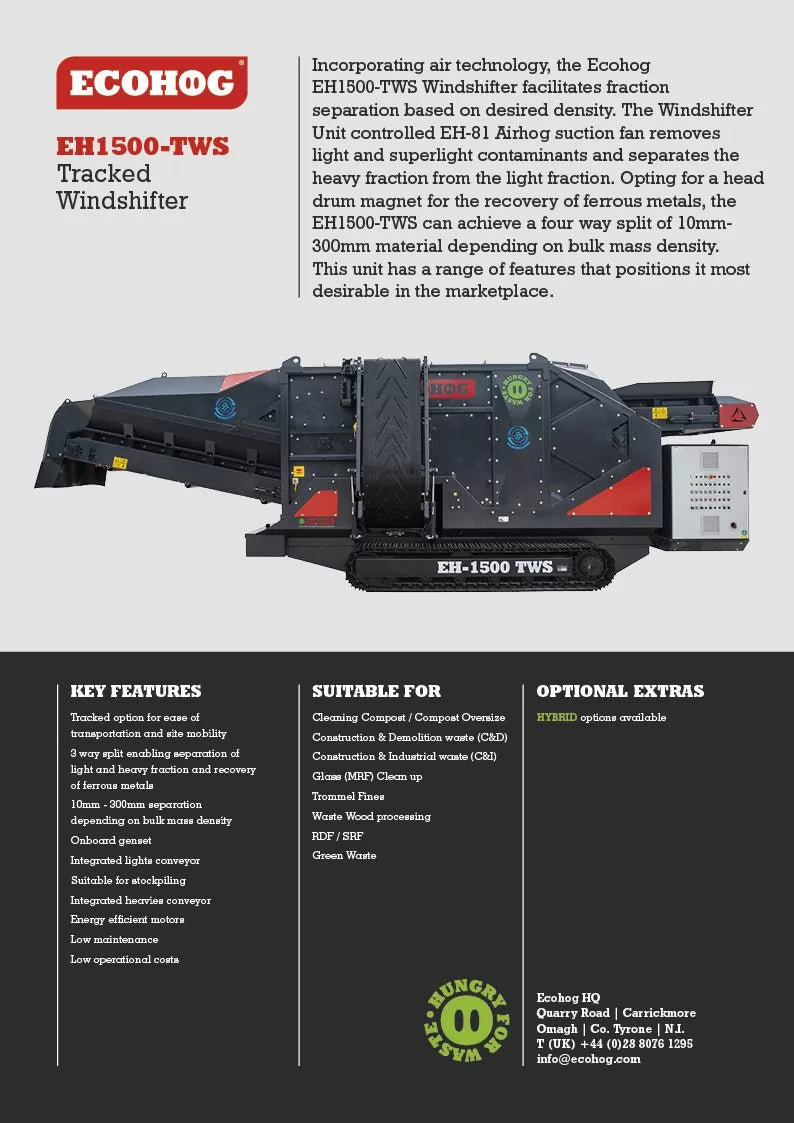

The EcoHog EH1500-TWS Tracked Windshifter is designed for efficient density separation with easy setup and excellent mobility. It features discharge conveyors and a magnetic head pulley to remove metals and heavy materials from waste. Suitable for materials up to 300 mm (12"), it uses advanced air technology with the EH-81 Airhog suction fan to separate light and superlight contaminants from heavier fractions. The head drum magnet enables ferrous metal recovery, allowing a three-way split of materials between 10mm and 300mm based on bulk density. Key features include a tracked chassis for transport, onboard genset, integrated lights fraction cover, energy-efficient motors, and low maintenance, making it ideal for scrap metals, compost, construction and industrial waste, glass, wood processing, and more.

The EH1500-TWS Tracked Windshifter is engineered for precise material separation with advanced components and robust construction. It features a 1500mm wide EP 400/3 accelerator belt with variable speed up to 1.6 m/s, powered by a 4.0kW drive. Two 7.5kW blower fans with variable speed drives create optimal airflow through an adjustable inlet, ensuring efficient separation between the drum and conveyor belt. The 550mm diameter steel separator drum, driven by a 3kW motor, uses counter-rotation to direct heavy materials toward the discharge conveyor. The dispersion chamber allows material to settle, recycling 90% of air while venting 10%, and includes a steel curtain for container lining. Constructed with bevelled profile and sheet steel, the housing incorporates legs with a support mechanism to lift the cyclone and baffles to guide light and heavy fractions. The light fraction conveyor is in-line with a 1500mm wide EP250/2 ply belt driven by 4.0kW, while the heavy fraction conveyor runs perpendicular with an 800mm wide belt, also powered by 4.0kW. A ferrite permanent 360° head drum magnet on the heavy conveyor recovers ferrous metals. The tracked undercarriage includes right and left track frames with 52-link steel tracks featuring 400mm wide triple grouser shoes, lifetime-lubricated rollers, heavy-duty sprockets, and integrated motion control valves. Hydraulic systems enable raising and lowering of conveyors, and crawler tracks facilitate easy on-site movement and loading. Controls include sequenced operation with variable speed drives for the accelerator belt, drum separator, and blower fans, plus direct-on-line drives for conveyors. Manual lever adjustment for the accelerator belt position and dog lead remote control enhance usability. Power options include a 60KVA Tier 5 generator set, ensuring reliable operation in diverse environments.